Welcome To VH-MARINETECH CO.,LTD. Website

Toggle Navigation

1. connecting aft manifold and tail hose

2. lifting lugs should be able to sustain loads, minimum breaking load is 12”=100KN 16”=150KN 20”=200KN

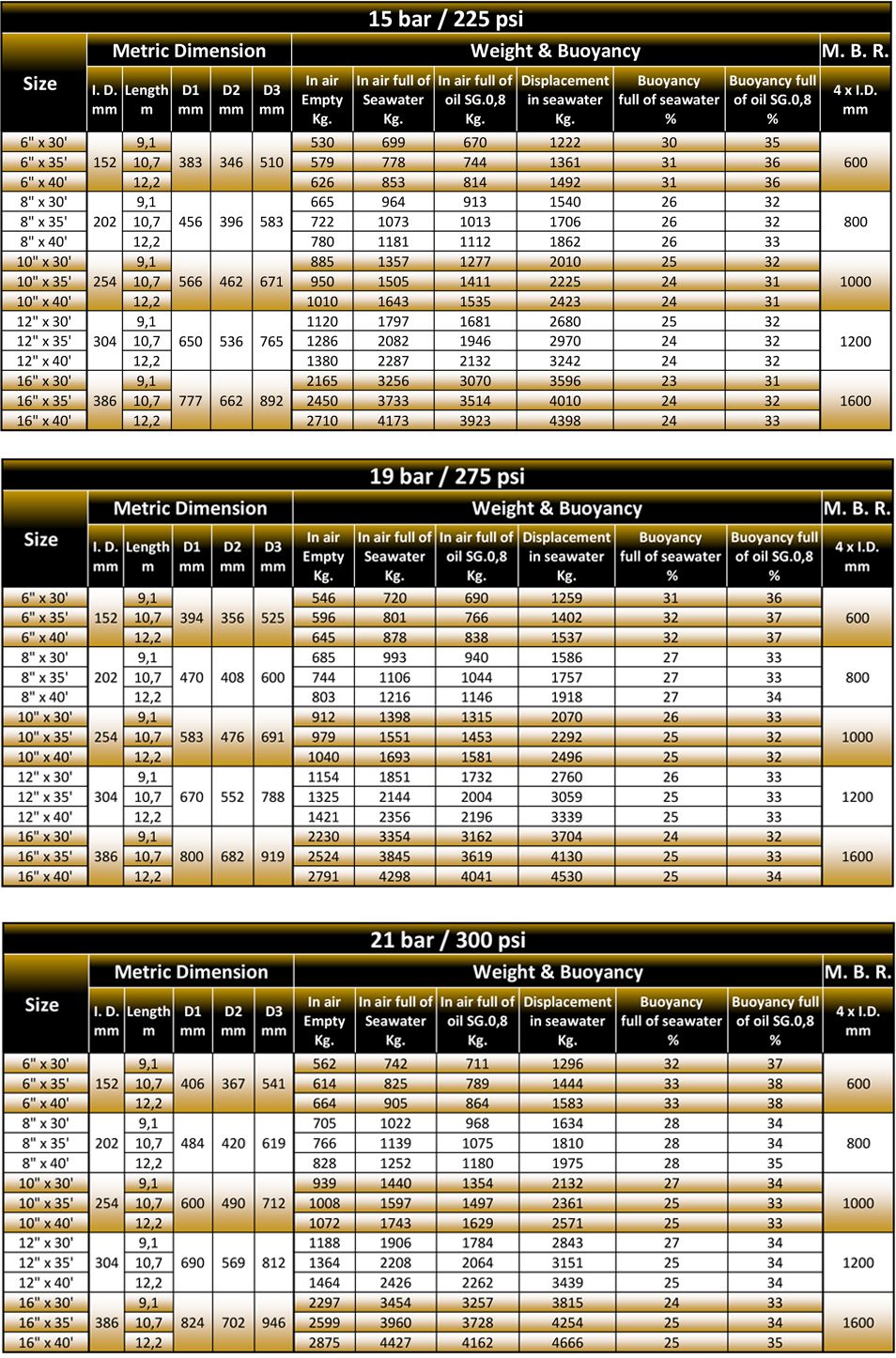

3. rated working pressure: 21 bar

4. minimum reserve buoyance: 20% or according to customer requirements

5. electrical continuity: electrical continuous or discontinuous

6. leak detection system: after the failure of the primary carcass, the detector will react to the leakage to remind the operator to remove the damaged hose to avoid economic loss and environmental pollution.

7.cover: PU or rubber

Specifications can be designed by customer requirements.

Tanker Rail Barbell Buoyant Hose Main Carcass:

●Main Lining / Inner Tube: Smooth, oil and fuel resistant Pure Seamless and Extruded Acrylontrile-Butadiene-Rubber (NBR);

●Safety Lining: special construction to prevent defects or damage cause by incidental tearing or superficial damages of the main linig;

● Reinforcements: Multiple Plies of High Tensile Textile cord. One embedded helical Body Steel wire.

● Cover: Black Syntetic Rubber Smooth oil and fuel resistant.

● Single Carcass And Double Carcass

Tanker Rail Barbell Buoyant Hose Floatation:

● Floating Material : Closed cell Foam.

Tanker Rail Barbell Buoyant Hose Outer Cover:

● Smooth black, Synthetic Rubber Resistant to Abrasion, Oil, Sea Water and Sunlight.

● Helical Orange strip.

● Polyurethane Orange in Colour cover available on request.

Tanker Rail Barbell Buoyant Hose Fittings: End connections built in during manufacture. ASME B 16.5 Class 150lb or 300lb Weld Neck Flat Face or Raised Face on request.

Tanker Rail Barbell Buoyant Hose Tests: All tests according to GMPHOM 2009 and Customer detail.

Online

Online 008613393047135

008613393047135 [email protected]

[email protected] +86 13393047135

+86 13393047135